Startseite » Calf feeding – Förster-Technik » MilchMobil NEXT » Clean & Fill Station

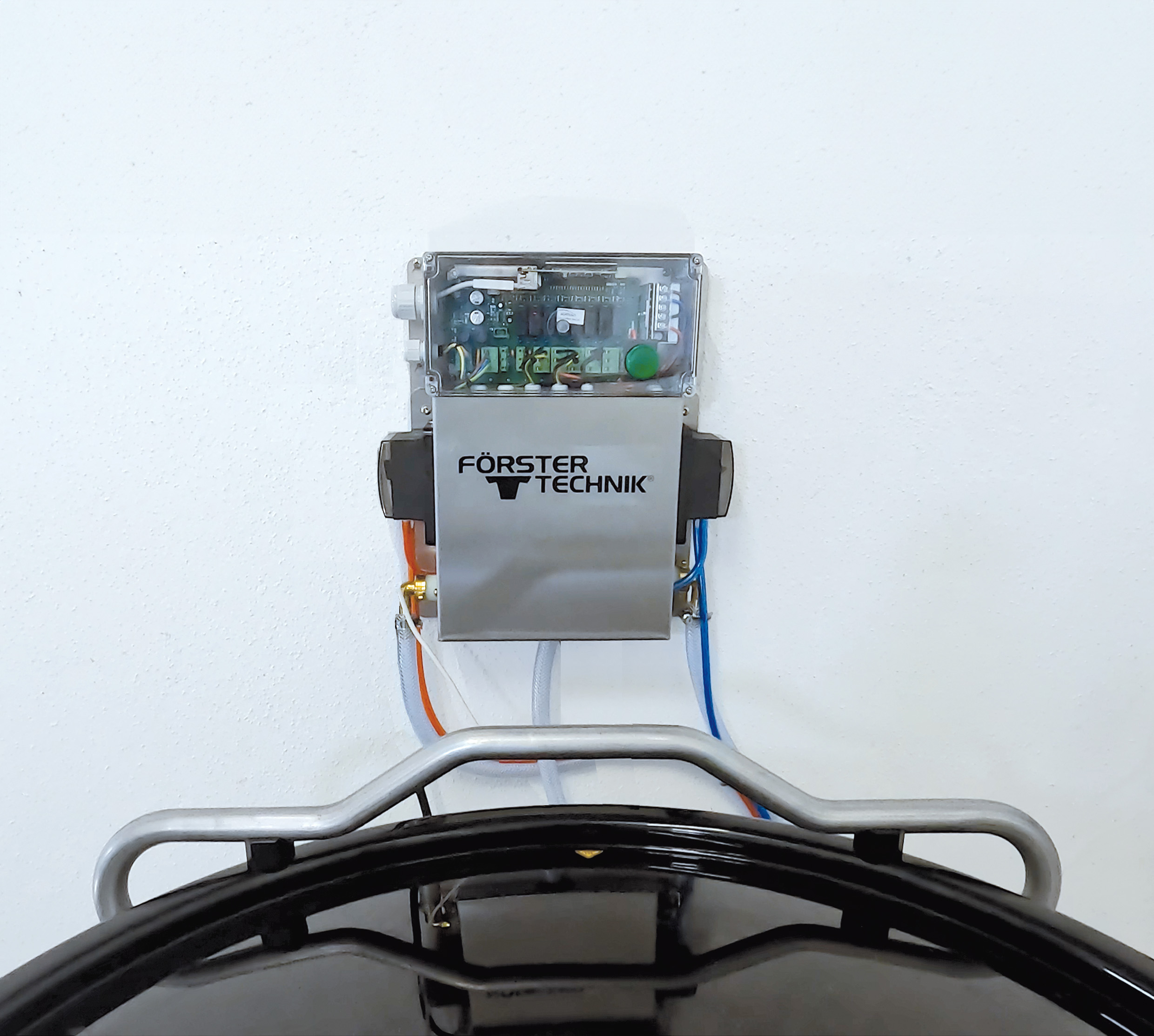

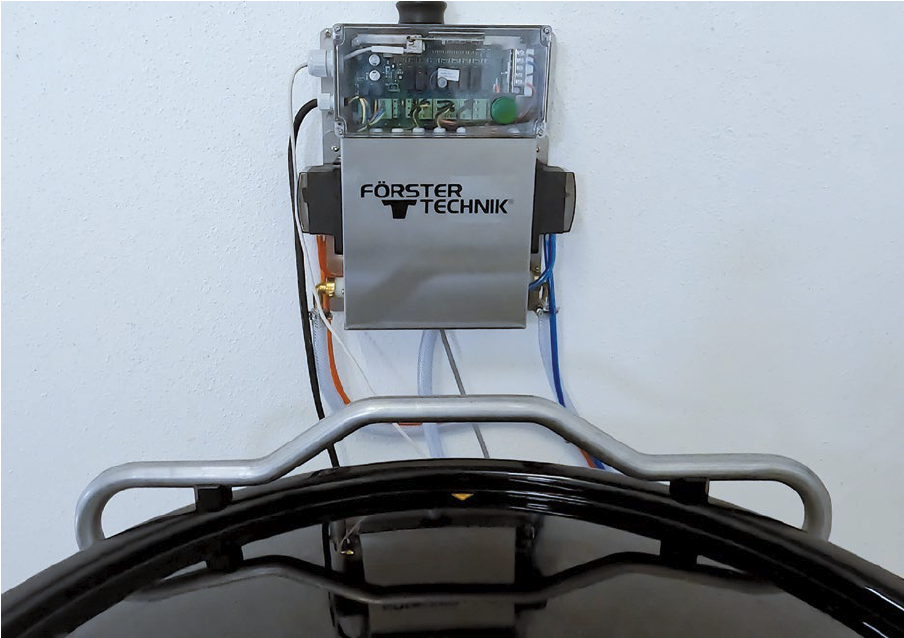

The Clean & Fill Station consists of a compact control unit that can be easily attached to the wall in the dairy kitchen. Until now, the manual cleaning of all milk-carrying parts such as the tank, pump, hose and dosing gun after feeding was time-consuming and annoying. Just like waiting for the water to fill up and heat up before feeding with milk replacer. The Clean & Fill Station now automates these two steps. Simply dock the MilchMobil NEXT onto the Clean & Fill Station. Then start the cleaning or filling program and all milk-carrying parts are perfectly cleaned, the water for the next feeding is filled in and heated up. Just fill in the milk replacer and drive off. The Clean & Fill Station can be connected to the MilchMobil NEXT in just a few simple steps and reduces the time required for cleaning and filling to one minute per feeding cycle.

MILKMOBILE NEXT. AUTOMATICALLY READY TO FEED.

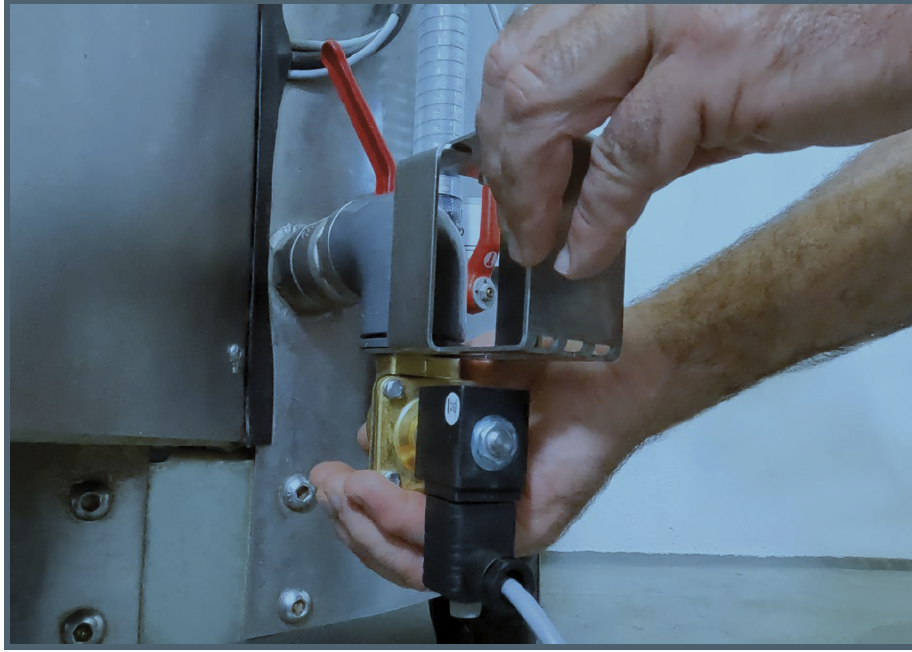

In addition to a cold and hot water connection, the Clean & Fill Station has two detergent pumps for alkaline and acidic detergent. Only three connections need to be connected to the MilchMobil NEXT. A hose with quick coupling for the supply of water and detergent, the drain valve for the tank and a data connection. As with manual cleaning, the cleaning nozzle must be connected to the dosing head of the milk hose and inserted into the center of the tank lid.

The ‘docking’ process is completed within a minute. There are two cleaning programs to choose from: Cleaning with alkaline and acidic detergent alternately or rinsing with clear water.

AUTOMATIC CLEANING OF THE MILKMOBILE NEXT.

The cleaning process is fully automatic and involves the following steps:

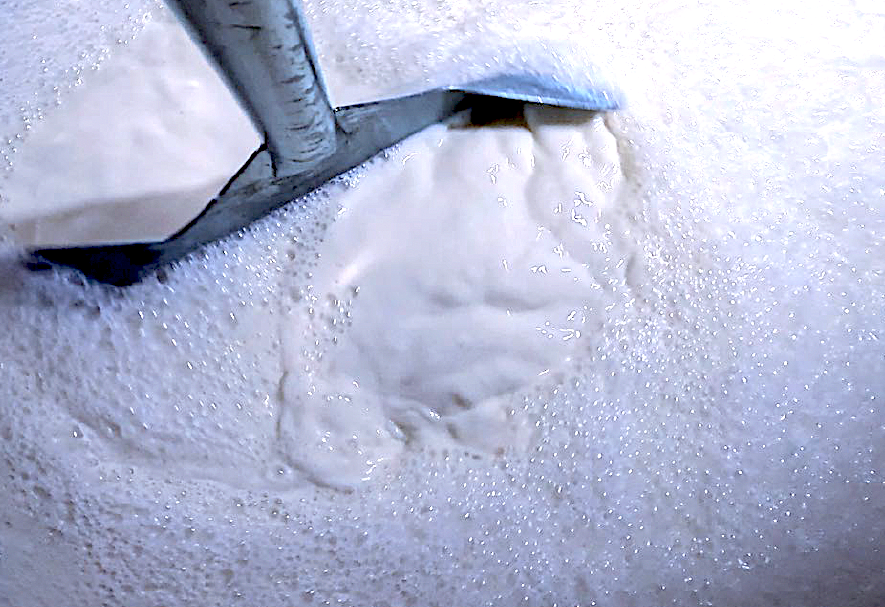

- Pre-rinsing the tank with clear water via the cleaning nozzle and subsequent emptying of the tank

- Introduction of warm cleaning water or heating the water to cleaning temperature, dosing the correct amount of cleansing agent, main cleaning of the tank and all milk-carrying parts by circulating the rinsing water via the cleaning nozzle, draining the cleaning water

- After rinsing with clear water, the milk tank is completely emptied via the drain valve and left to dry until preparation of the next feeding. This corresponds to good operational practice for milk tank cleaning. Optimum cleaning results and a high standard of hygiene are guaranteed.

AUTOMATIC WATER FILLING FOR THE NEXT FEEDING.

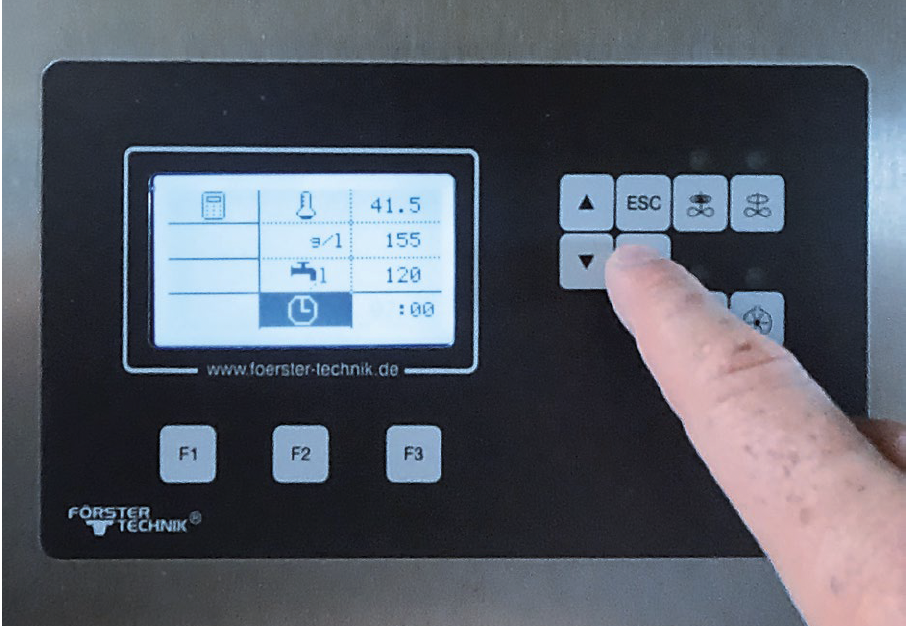

Depending on the livestock, up to 250 liters of water are required per feeding to prepare the milk powder/water feed. After the desired amount of feed has been specified, the water sensor automatically releases the exact amount of water into the tank. It is timed so that it is ready for the next feeding at the correct mixing temperature. If hot water is available, for example from a biogas digester, the tank can be filled with hot water, thus saving electrical heating energy. The operator arrives at the MilchMobil NEXT shortly before feeding time and has only to fill in and stir the desired amount of milk powder. The MilchMobil NEXT calculator also provides support here and displays the amount of milk powder to be added according to the number of animals. The annoying and time-consuming waiting when filling and heating up is now a thing of the past.

THE CORRECT DRINKING TEMPERATURE - COMPLETELY AUTOMATIC.

For optimum mixing of large quantities of milk powder in water, 2/3 of the water quantity is first filled in and heated to a mixing temperature. The required amount of milk powder is displayed and only needs to be added and stirred by the operator. The Clean & Fill Station then fills in the remaining amount of cold water so that the exact drinking temperature is achieved and kept constant until feeding begins.

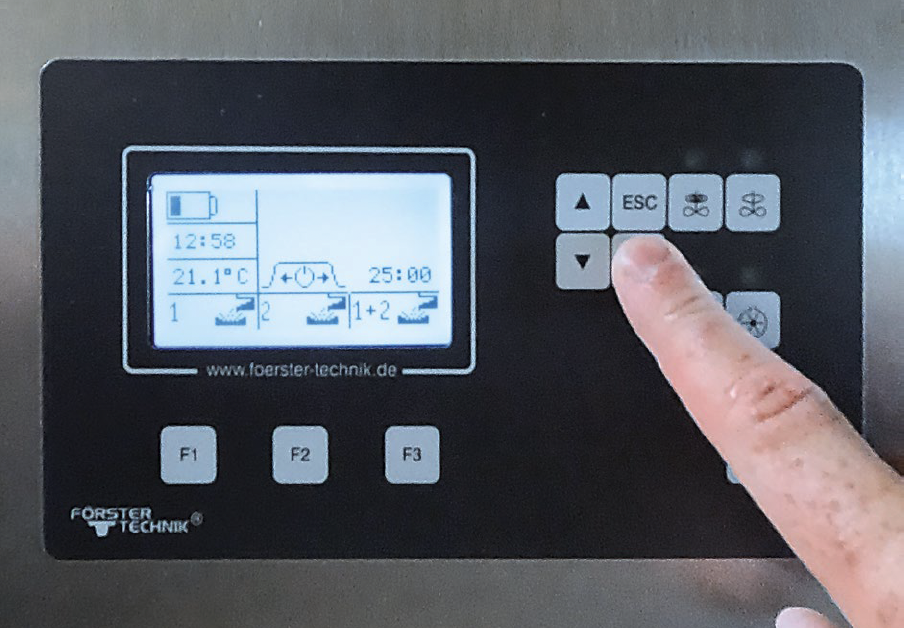

FUNCTION CONTROL VIA THE MILCHMOBIL NEXT.

All functions of the Clean & Fill Station are controlled via the MilchMobil NEXT.

All parameters for cleaning and feeding preparation can also be set individually on the device. The operating status of the Clean & Fill Station is clearly indicated by colored lights. Thanks to the data connection between the Clean & Fill Station and the MilchMobil NEXT, all processes are aligned with each other. This means that the components of the MilchMobil NEXT such as the pump, heater, temperature sensor, level sensor etc. can be integrated into the automation process. Farmers only have to adapt to one operating philosophy. Not only simple and practical, but highly economical.

SAVE A LOT OF TIME AND MONEY WITH THE NEW CLEAN & FILL STATION.

Manual cleaning by one person takes at least ten minutes. With two feedings per day, this corresponds to 20 minutes per day and therefore approx. 120 working hours per year. The automatic filling of water for the next feeding saves another 10 minutes of waiting time per feeding. That is another 120 hours per year. At an hourly rate of €20, that is €2400 per year. The Clean & Fill Station thus pays for itself within 10 months.